OEM Caster PU Wheel PP Castor China Suppliers Swivel Stem Ka brake

PU caster ea maemo a holimo

Super muting PU caster

Super PU caster caster

Rabara ea maiketsetso ea matla a phahameng

Caster ea maiketsetso e tsamaisang rabara

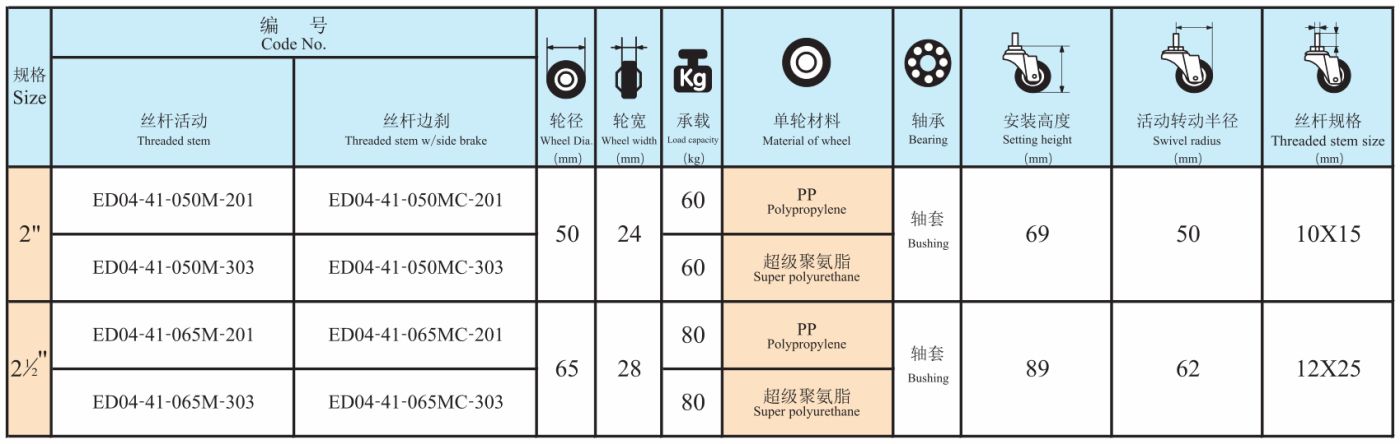

| Boholo | Nomoro ea khoutu. | Wheel Dia. (mm) | IBophara ba lebili (mm) | Boima ba moroalo (kg) | Lintho tsa lebili | Bearing | Bophahamo ba ho beha (mm) | Swivel radius (mm) | Boholo ba kutu e khoele (mm) | |

|

Lehlaka le nang le likhoele |

Kutu e nang le likhoele e nang le brake ea lehlakore | |||||||||

| 2n | ED04-41-050M-201 | ED04-41-050MC-201 | 50 | 24 | 60 | PP Polypropylene |

| 69 | 50 | 10X15 |

| ED04-41-050M-303 | ED04-41-050MC-303 | 60 |

Super polyurethane | Bushing | ||||||

| 2X" | ED04-41-065M-201 | ED04-41-065MC-201 | 65 | 28 | 80 | PP Polypropylene |

| 89 | 62 | 12X25 |

| ED04-41-065M-303 | ED04-41-065MC-303 | 80 |

Super polyurethane | Bushing | ||||||

1. Lisebelisoa tsa boleng bo holimo tse rekiloeng ka tlhahlobo e tiileng ea boleng.

2. Sehlahisoa se seng le se seng se hlahlojoe ka thata pele se paka.

3. Re moetsi oa litsebi ka lilemo tse fetang 25.

4. Taelo ea teko kapa litaelo tse tsoakiloeng li amoheloa.

5. Litaelo tsa OEM lia amoheloa.

6. Ho tsamaisoa kapele.

7) Mofuta ofe kapa ofe oa li-casters le mabili a ka etsoa ka mokhoa o ikhethileng.

Re amohetse theknoloji e tsoetseng pele, lisebelisoa le lisebelisoa tsa boleng bo holimo ho netefatsa ho tenyetseha, bonolo le ho tšoarella ha lihlahisoa tsa rona.Maemong a fapaneng, lihlahisoa tsa rona li na le ho senyeha, ho thulana, ho senyeha ha lik'hemik'hale, ho hanyetsa mocheso o tlase / o phahameng, ho se na pina, tšireletso ea fatše le likarolo tse tlaase tsa lerata.

Teko

Workshop

1. 'Mala oa filimi ea oxide ea moea:' mala o lokela ho ba le ka mor'a hore e be bluish, 'me ha ho na matheba le karolo ea filimi ea oxide ea moea e sa lumelloeng.Ka lebaka la boreleli bo fapaneng ba bokaholimo ba karolo e le 'ngoe, kapa likarolo tse nang le kalafo e sa fellang ea mocheso kapa boemo ba welding ea motlakase, phapang ea mebala e lumelloa.Ka mor'a hore likarolo tsa tšepe tsa carbon le li-alloy li fetohe putsoa, ho lokela ho ba le filimi ea symmetrical black air oxide.Li-castings le likarolo tse nang le silicon tse nang le carbon steel li lumelloa ho ba mosehla o sootho kapa o lefifi ka mor'a ho fetoha boputsoa.

2. Matla a hatellang a filimi ea oxide ea moea: Filimi ea oxide ea moea le fusion e kholo ea matla a khatello, itlotsa ka thata ka lesela le omeletseng, 'me u se ke ua bontša sebopeho sa tšepe.

3. Ho tiea ha filimi ea air oxide: Ha likarolo li fetoha boputsoa, sebelisa tharollo ea sodium thiosulfate ea 3% ho senya metsotsoana e ka bang 30 pele u sebelisa oli, 'me ha ho electroplating ea koporo e lumelloang holim'a likarolo.Leha ho le joalo, palo e nyane ea matheba a koporo a ka hlaha ka mathōko a nchocho, likhutlong le libakeng tse chesellang.

4. Anti-corrosion ea filimi ea oxide ea moea: e silafalitsoeng ke 3% ea tharollo ea letsoai e jeoang bakeng sa lihora tse 3 ntle le ho senya.

5. The boreleli ba likarolo le eona: Ka mor'a ho hloekisa bluing, tlohela marotholi a 1-2 a phenolphthalein alcohol solution holim'a sehlahisoa sa sehlahisoa.Ka mohlala, tharollo ea joala ea phenolphthalein e pinki e mosehla, e bontšang hore ho hloekisa ha hoa hloeka.